Custom Heavy Lifting Equipment Fabrication for the Railroad Industry

Custom-Engineered Lifting Solutions for Rail Infrastructure and Maintenance

Client: National Railroad Service Contractor | Industry Leader in Rail System Efficiency

Project Overview

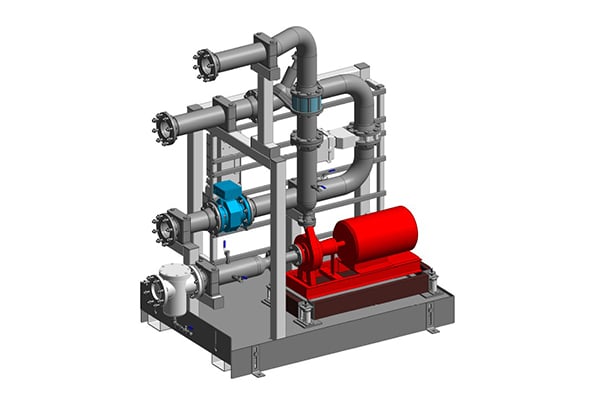

A national railroad contractor required a specialized heavy-lifting system that was not available in the market. They turned to Magna Fab’s engineering and fabrication team to develop a custom-built lifting device designed for durability, safety, and seamless functionality in demanding rail applications.

Challenges & Objectives

- Custom industrial design tailored for railroad applications

- High-strength metal fabrication and precision welding for long-term reliability

- Compliance with ASME and AWS welding standards

- Fast-track production schedule to meet operational deadlines

Magna Fab’s Custom Fabrication Process

- CAD modeling and structural analysis to optimize load distribution

- Prototype fabrication and real-world performance testing

- ASME-compliant engineering validation and third-party certification

- Full-scale metal fabrication using CNC cutting, AWS-certified welding, and industrial coatings

Results & Benefits

- Heavy-duty lifting system engineered for high-load rail applications

- ASME and AWS-certified fabrication ensuring maximum durability and safety

- Rapid production and scalable manufacturing capabilities

Why Magna Fab for Custom Industrial Equipment?

Magna Fab specializes in custom metal fabrication, precision welding, and ASME-certified manufacturing for industries requiring heavy-duty, high-performance solutions.